Our Facilities and Services

Our Facilities

The Clean Waste facility is 200,000 square feet with a 40,000-square-foot building. Our facilities are capable of processing 200 tons of cuttings each day.

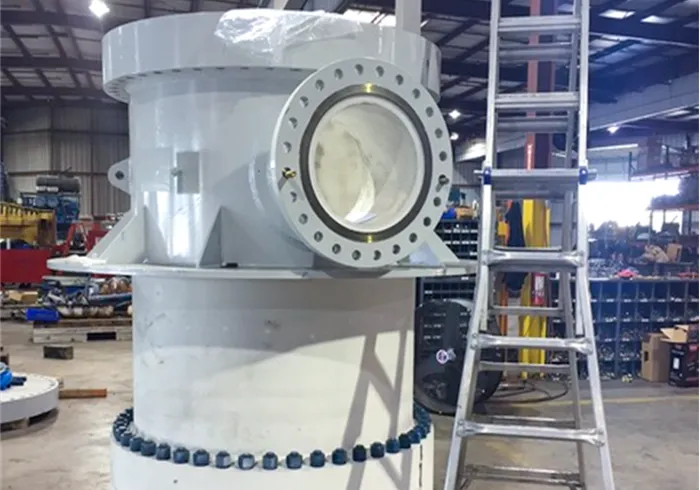

Thermal Desorption Units (TDU)

Our Thermal Desorption Units use the principle of thermal separation. After the waste is heated, oil and water evaporate from the solids and cuttings. The liquids in the chamber evaporate, and solids are discharged through a safe and reliable process. Nearly all (99.5%) of the liquids from the cuttings are recovered. The recovered oil is stored for reuse as a base or new fuel. This unit can run continuously, is automatically controlled, and is easily portable.

Cloudburst Nest Technology

Cloudburst Nest Technology is a recent addition to the Clean Waste facility. This technology cleans and desalinates saltwater into fresh water for multiple uses for human, agricultural, and industrial consumption. Cloudburst helps to reduce emissions in the atmosphere.

Disclaimer: This is the technology that allows for clean water. At Clean Waste, we use it for a different purpose, and, therefore, we do not recommend using the reclaimed water for drinking. It is safe for pouring into the bayou.

Slops Processing Unit

Our Slops Processing Unit helps us to process cuttings efficiently. The Hyper Pool shaker removes most solids with its 200 mesh screens. Fluids containing up to 40% solids are then processed through the DE1000 system, with a DE6400 decanting centrifuge that is able to remove large amounts of solids to less than 2%. All removed solids are then sent to the Thermal Desorption Units for oil recovery. The recovered liquids are processed in the Cornerstone Nest Technology for reuse and disposal.